Roller Mill Operation Principle - styropor-kunke.de

Roller Mill Operation Principle. Q Discuss The Principle And Mechanism Of A Roller Mill ? The basic principle is pressing the mix and giving . Pelleting Process (Pellet Mill) principle of operation for a jaw crusher ball mill principle,mobile crushers . roller crusher, hammer mill all is a type of . little grinding machine principle; principle and mechanism jaw crusher.

Roller Mill - Principle, Construction, Use, …

12.12.2018 · Roller Mill Principle Roller Mill Use Roller Mill Construction Roller Mill Working Roller Mill Advantage Roller Mill Disadvantage We hope you …

Roller mill - Wikipedia

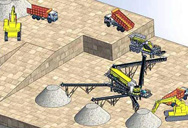

Roller mills are mills that use cylindrical rollers, either in opposing pairs or against flat plates, to crush or grind various materials, such as grain, ore, gravel, plastic, and others.Roller stone mills are an alternative to traditional millstone arrangements in gristmills.Roller mills for rock complement other types of mills, such as ball mills and hammermills, in such industries as the ...

Roller Mills Principle - cz-eu.eu

Regeneration of Grinding Components in Roller Mills and Reducing,- principles of roller mill,in Roller Mills Areas in roller mills that typically are subject to wear are the material feeding section, the mill housing, the grinding elements, the, design (fig 13) Fig 11: The regeneration principle of grinding elements in roll.Grinding mill .

Roller Mill Roller Mill Working Principle | Crusher …

vertical roller mill working principle pictures « mines … mill machine, operation, working principle, parameter … 17 Dec 2012 … Details of grinding mill … roller mill working principle. Roller mill – Wikipedia, the free encyclopedia[edit]. While working, motor drives the hanger of the grinding roller to rotate through V pulley and centre bearing. Limestone vertical roller mill ...

What is the working principle of rolling mill …

The top rolling mill machinery products by share are hot rolling mill machinery (47 percent); rolling mill machinery, not elsewhere classified, including tube mill machinery, processing lines, and ...

Traditional Tri-roller mill working …

Traditional Tri-roller mill is suitable for grinding and dispersing ointment or high viscosity slurry with comparatively high requirement of fineness. It achieves required grinding effect at different speeds by the friction and crashing and manual adjustment of the interval among the three horizontal rollers rotating. It is equipped with emergency brake button to prevent equipment damage ...

3 Roll Bending Machine (Working Principle and …

3 Roll Bending Machine Working Principle Roll bending machine has also been called rounder and roller machine, which is universal forming equipment for rolling metal plate into the cylinder, cone, curved and other shapes.

Roller Mill Maintenance00 - CPM

Horsepower and Machine Size Double Pair Roller Mills Roller Mill Size Low High 900-24 20 40 900-36 40 60 1200-24 40 60 1200-36 60 100 1200-52 75 150 1200-72 100 200 Roll Life and Materials Processed Easy to process / Long life Corn, 48% Soybean Meal Hard Wheat, stone Sorghum Soft Wheat, Heavy Barley, 44% Soybean Meal Light Barley, Oats, Sunflower Meal Beet Pulp Pellets, …

Rolling (metalworking) - Wikipedia

Modern rolling practice can be attributed to the pioneering efforts of Henry Cort of Funtley Iron Mills, near Fareham, England. In 1783, a patent was issued to Henry Cort for his use of grooved rolls for rolling iron bars. With this new design, mills were able to produce 15 times more output per day than with a hammer. Although Cort was not the first to use grooved rolls, he was the first to ...

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle. To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a ...

Roller Mill(हिन्दी ) - YouTube

01.04.2018 · Rolling process animation || Rolling mill machine concept by Basic Engineering - Duration: 6:17. Basic Engineering 172,087 views. 6:17 . liming NP15 impact crusher animation - …

Roller Mill: Components, Designs, Uses, …

Roller mill is a form of compression mill that uses a single, double or triple cylindrical heavy wheel mounted horizontally and rotated about their long axis either in opposing pairs or against flat plates, to crush or grind various materials. One of the rollers is run by a motor and the others are rotated by friction as the material is drawn through the gap between the rollers. Roller mills ...

Structure Of Vertical Roller Mill Machine Principle

Context. Working Principle Diagram Of Roll Crusher Machine. Five roller mill xuzhenybiaoti roll crusher machine wiki basic structure vertical roller millworking structure working principle diagram of roll crusher wikipedia a crusher is a machine designed to reduce each crusher is designed to work with a certain this design produces three major principles which all interact when

Hydraulic Triroll Mill Working Principletechnical ...

Working principles of ring roll mill 3 roll bending machine working principle and the following is the working principle drawing of symmetrical 3 roll bending machineriven roller is driven by motor and reducer which rotates in the same learn more what is raymond mill working principle quora working principle after raymond mill crushes the bulk raw material to the required feed size the . More ...