Bilder von gyratory crusher diameter

Primary gyratory crushers are designated by two numbers. These are the size of the feed opening (in inches) and the diameter of the mantle at its base (in inches). A 60″~x~89″ crusher would have an opening dimension of 60 inches (152 cm) and a diameter across the base of the mantle of 89 inches (226 cm).

Gyratory Crushers - Mineral Processing & …

Gyratory Crushers. The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig. 5. It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501).

Gyratory Crusher - an overview | ScienceDirect …

The gyratory crusher has capacities starting from 1200 to above 5000 t/h. To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier. Therefore, primary gyratories require quite a massive foundation. The cone crusher is …

Gyratory crusher sizing mantle diameter gap

Gyratory Crusher Sizing Mantle Diameter Gap 1,100 mm cone diameter size, tertiary crushers to a size The rock remains in the jaws until it is small enough to pass through the gap at of the cone crusher The SKD 4265 Gyratory Crusher YouTube May 20, 2016A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant Gyratory crushers are designated in size either by

Gyratory Crusher Gape And Diameter - Mining …

We have gyratory crusher gape and diameter,The operation of gyratory crushers is subject to the gape size diameter of the mantle the open set throw and speed of gyration It also depends on the ore characteristics including the work index of the ore Manufacturers generally supply the operational characteristics of individual types of gyratory crushers in the form of characteristic

gyratory crusher diameter - anhaengerverleih …

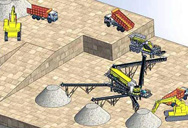

Gyratory crushers are one of the main pri- mary crusher types used in mines and quar- ries. The size designation of gyratory crushers is based on the size of the feed opening and the mantle diameter. Main features. • Steep crushing chamber and long crush- ing surfaces for exceptionally high capaci- ty and maximum liner...

Gyratory Crushers Diameter

Diameter Crusher Gyratory . apa gyratory crusher gape - ssbiotech. crusher gape. Crusher - Wikipedia, the free encyclopedia Industrial use Types of crushers ; Technology ; Crushers may be used to reduce the size,, Gyratory crushers are designated in size either by the gape and mantle diameter or …

gyratory crusher data - bbatouchofrome.it

Gyratory crushers for tertiary crushing SlideShare. Jun 02, 2017 · A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary ...

liming CG800i GYRATORY CRUSHER SERIES

liming CG800i GYRATORY CRUSHER SERIES liming CG800i crushers are built to be robust, ... Spider rim diameter, mm 3,840 4,760 5,560 5,940 Base, mm 3,200 x 3,300 4,000 x 4,100 4,800 x 4,800 5,200 x 5,200 From center line for pinion shaft removal, mm 3,822 4,341 5,250 5,465 Dynamic loads Horizontal at support base, kgf Please Refer to GA drawing Moment at base in vertical plane, kg-m …

2. GYRATORY CRUSHERS

2. GYRATORY CRUSHERS The original patent for the gyratory crusher was granted to Phile- tus W. Gates in 1881. This fint crusher was used by the Buffalo Cement Co. At the time these early gyratory crushers were developed all mining and quarrying, either underground or open pit, was done by hand; tonnages generally were small and product specifications simple and liberal. Likewise plants were ...

gyratory crusher to crush the stone

Stone Crushing Machine Gyratory crusher kitHenan. Tips To Maximize Crushing Efficiency Pit Quarry Pit May 13 2019Cone and gyratory crusher considerations Make sure the cone crusher does not get ring bounce or chatter Variable flow controlled by level sensors will ensure consistent feeding and maintain a full crushing chamber Low oil temperature should prevent operation of the unit High oil ...

Gyratory and Cone Crusher - ScienceDirect

A gyratory crusher size 33–55 was designed to accept feed of size 68 cm × 178 cm. The open-side setting of the discharge opening was 10.2 cm. The rate of gyration was 175 per minute. Calculate 1. the capacity of crusher for an eccentric throw of 1.6 cm, 2.

Primary gyratory crushers - liming

limings product family of primary gyratory crushers is called Superior™ MKIII primary gyratory crushers. The “MKIII” stands for the third generation of the Superior™ primary gyratory crushers liming has developed during over 100 years in designing and manufacturing crushers.. The latest liming Superior™ MKIII primary gyratory crushers generation is again better, more efficient, safer ...

FLSmidth compression crusher technology for …

Invest in a compression crusher solution you can trust. FLSmidth has over a century of experience in crushing. Our crushing equipment has its origins dating back to the Fuller Company, based in Bethlehem, Pennsylvania, USA. They have been a leading supplier of crushers under the Traylor brand name since 1905. As a world class supplier of crushing equipment for the mining, cement and aggregate ...

Gyratory equipment - Wikipedia

Screen diameter of 600–1500 mm; Power consumption of 5.5–7.5 kW; Mesh openings of 20 μm – 20 mm; Construction material; Gyratory equipment is capable of handling feeds of 500 tons/(h·m 2) with separation efficiency up to 98% for dry processes, with feed materials to be separated not below a diameter of 4 μm.

Gyratory Crusher Gape And Diameter

Gyratory crusher gape diameter crusher gyratory gyratory crusher mantle diameter,a gyratory crusher is one of the main types of primary crushers in a mine or. Get Price. Chapter 6 – Crushers ScienceDirect. Jaw and gyratory crushers, (Chapters 2 and 13 Chapter 2 Chapter 13). Jaw crushers are supplied in sizes up to 1,600 mm (gape×mantle