Copper-Nickel Ore Processing - 911metallurgist.com

Copper Solvent Extraction The separation of copper from nickel is based on the fact that there is an appreciable difference in the pH at which the two metals are extracted. Copper can be extracted, with very small amounts of nickel, at pH 6.0 to 6.5, while nickel is extracted from the copper …

Nickel processing - Extraction and refining | Britannica

In cases such as the Sudbury deposit, where the copper content of the ore is almost equal to that of nickel, the concentrate is subjected to a second selective flotation whereby the copper is floated to produce a low-nickel copper concentrate and a separate nickel concentrate, each to be processed in its respective smelting line.

Nickel processing | Britannica

Chalcopyrite, CuFeS 2, is the dominant copper mineral in these ores, with small amounts of another copper mineral, cubanite, CuFe 2 S 3. Some gold, silver, and the six platinum-group metals also are present, and their recovery is important. Cobalt, selenium, tellurium, and sulfur may be recovered from the ores as well.

Copper Ore Processing Methods

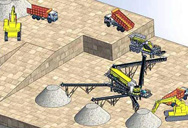

Copper Ore Processing Methods. The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining. In a few instances, however, leaching takes the place of concentrating, smelting, and refining. At present, although considerable leaching and direct-smelting ores are produced, the bulk of the copper ore mined is concentrated.

Nickel Mining and Processing: Everything you Need to Know

More than 1.4 million tons of primary or new nickel is produced worldwide. This compares to 800 million tons of steel and 10 million tons of copper. The Nickel Mining Process. Nickel mining occurs through extractive metallurgy, which is a material science that covers various types of ore, the washing process, concentration and separation, stone processes and the extraction process.

Copper-Nickel ores - Danafloat

Separation of the bulk concentrate copper and nickel minerals is generally accomplished by flotation of the copper from pentlandite and nickel-bearing iron sulphides which report to the flotation tails. Pentlandite and iron sulphides are depressed by raising the pH …

Copper Mining and Processing: Processing of Copper Ores ...

This process uses aqueous (water-based) solutions to extract and purify copper from copper oxide ores at ordinary temperatures, usually in three steps: heap leaching, solvent extraction, and electrowinning.

Copper extraction - Wikipedia

Copper extraction refers to the methods used to obtain copper from its ores. The conversion of copper consists of a series of physical and electrochemical processes. Methods have evolved and vary with country depending on the ore source, local environmental regulations, and other factors.

Nickel: smelting, producing-Metalpedia

In hydrometallurgical processes, nickel sulfide ores undergo flotation (differential flotation if Ni/Fe ratio is too low) and then smelted. After producing the nickel matte, further processing is done via the Sherritt-Gordon process. First, copper is removed by adding hydrogen sulfide, leaving a concentrate of only cobalt and nickel. Then, solvent extraction is used to separate the cobalt and nickel, with the final …

Cobalt extraction - Wikipedia

Nickel-cobalt lateritic ores can be treated by either hydrometallurgical processes or pyrometallurgical processes, such as matte or ferronickel smelting, which require the entire ore to be melted and the metal values to be separated from the residual components of the ore. The hydrometallurgical process for laterite ore can use sulfuric acid or ammonia leach solutions.

Chapter 6 Copper Production Technology

Copper ores 0.2-6.0 Copper ore, other minerals, waste rock0.2-6.0 (gangue) Copper minerals,b iron and other metallic0.5-6.0 pyrites, byproducts, andgangue Solution of copper and leaching agent20-50 (water orHAO.) Copper, iron (0.2-2.00/0), trace amounts of85-90 silica and aluminum oxides, and oxygen Organic solvent and pregnantIeachate; 25-35

Copper. One more ore processing - YouTube

Mar 29, 2017 · Copper and tin give us bronze, and alliance with nickel turns copper into melchior. Copper presents in Olympic medals of two values. Bronze medal contains about 97% of copper…

Nickel Ore Mining Process - Xinhai

Copper- Nickel Ore Flotation Process. When process copper-sulfide nickel ore, collector and frother will be used in order to better results. A basic principle of copper-sulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite. For it is easier to recovery cooper from nickel concentrate.

Nickel Sulfide Versus Laterite : The Hard Sustainability ...

different locations, depending on local geographic factors. The processing of sulfide ores in this manner is known as pyrometallurgy, with copper (Cu) either an important by-product or co-product (depending on ore grades). Conversely, nickel production from laterite ores is …

Copper, Molybdenum, Nickel and Zinc Processing | Nalco Water

Copper, Nickel and Zinc DELIVERING A BROAD RANGE OF COPPER AND MOLYBDENUM PROCESSING SOLUTIONS From maximizing recovery to improving ore grade, your copper processing operation has unique needs that depend on a balanced and precise process.