Controlling Dust And Erosion In Quarries | Agg-Net

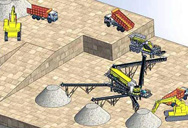

The need for dust control. Failure to limit dust and control erosion on site can have serious consequences, both in terms of operational efficiency and legal or statutory compliance. For example: the build-up of dust and deposits on operating equipment such as crushers, conveyors and screens increases the likelihood of: component failure ...

Effective dust control in quarries, mines – Quarry

Coolfog provides an effective, environmentally friendly and economical solution to managing dust within the quarrying and mining industries. Coolfog can be operated by stand-alone with remote control, hardwired or via SCADA and PLC systems. watch video

Quarries – A Solution or a Dust Problem? | Soil Solutions

Aug 02, 2017 · Quarry companies that do not show reasonable responsibility in limiting the dust they create should have financial consequences or even suspension – an example of this being implemented occurred in 2015 when the Ministry of Environment of the UAE suspended the operation permits of 14 quarry and crusher operators.

Dust Control Of Stone Crushers - lesgamapias.be

Dust Control System(Stone Crushers and Quarry) Dust is the major Pollution problem during the production of blue metals and Quarry transport Operations During the working of the stone crusher Dust comes out as a by-product This pollute the environment causing so many problems It can be better control by using "Thumba Dust Control System"

Crushers For Making Quarry Dust

The particles passing through 4.75mm sieve are called as quarry dust. The quarry dust is. Dust Control System Stone Crusher and Quarry Dust . Dust Control System(Stone Crushers and Quarry) Dust is the major Pollution problem during the production of blue metals and Quarry …

impact crusher dust control - hardpressed.co.za

Quarry Impact Crushers Dust Control Influence of crusher dust on the properties of concrete 41 respectively in comparison to that of control mix thus crusher dust can be used in place of sand yielding concrete,Quarry impact crushers dust control.

Dust control at limestone quarry | BossTek

Like most quarries, the company faces some difficult challenges in its attempts to control dust during extraction and processing. Operations such as quarrying, loading, transportation and mobile crushing typically don’t lend themselves to integrated suppression techniques, yet all of these add to the potential for releasing vast amounts of dust.

HSE - Quarries - Dust and silica

Dust and silica. By its nature quarrying has the potential to create dust. The control measures in place should prevent this reaching levels that will cause harm. Check the control measures in your workplace are identified in the health and safety document and that they work in your workplace.

Impact Crusher Dust Control Egypt

Dust Control System(Stone Crushers and Quarry) Dust is the major Pollution problem during the production of blue metals and Quarry transport Operations. Request Quotation dust supression system crusher quarry pdf. Used Impact Crusher Equipment Front Conveyor, Diesel Engine, Impact Crusher, Dust Control System.

Dust Control In The Aggregates Industry | Agg-Net

Two main issues drive dust control requirements: the first is environmental dust pollution in the area surrounding the quarry operations, which can have an adverse effect on the neighbouring community; and the second is the health of personnel who work in close proximity to high levels of dust emissions and, in particular, hazardous dust sources such as silica oxide from granite/quartz.

Gravel Pits, Quarries, and Aggregate Crushing and ...

In the case of most new gravel pits, an Act250 permit will likely be required and the AQCD will request that the permit include a condition requiring effective dust control. If your gravel pit or quarry will include drilling, sawing, blasting, or aggregate crushing operations then an air permit will likely be required.

Dust control for gravel pit crusher fines

Dust control for gravel pit crusher fines Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including, Dust control for gravel pit crusher fines, quarry, aggregate, and different kinds of minerals.

tn stone crusher unit dust control liming mining aug

tn stone crusher unit dust control BINQ Mining. 21 06 2013AP-42 Section Crushed Stone Processing and Pulverized This unit separates oversized rock from the smaller stone The undersized material Some stone crushing plants produce manufactured sand This is a to agglomerate on or to adhere to the faces of larger stones with a resulting dust suppression effect Screen and Crusher for Bristol ...

ntrol measures of ore quarry plant crusher for sale

Dust Ntrol For Crusher - tppvlaszak. Dust Ntrol For Crusher. Control measures of ore quarry plant crusher for sale dust suppression system for crushereb 13, 2016 nov 18, 2013 fogging systems, dust control, australia,, rainstorm dust controltone crusher dust orentrol measures ore quarry plant crusher …

dust control on vsi crusher

liming Vertical Impact Crusher Dust Control. Vsi stone crusher dust control systems even though the size of a jaw crusher can vary between around 1 and 300 tons the principle stays the same 1334 hsi and vsi crushers safety and control devices and dust control systems and the reliability is the most important thing vsi stone crusher dust control systems manufactured sand 247 online

quarry impact crushers dust control - thgroup.co.za

Dust Control System(Stone Crushers and Quarry) Dust is the major Pollution problem during the production of blue metals and Quarry transport Operations. During the working of the stone crusher Dust comes out as a by-product. This pollute the environment causing so many problems. It can be better control by using "Thumba Dust Control System".

Dust suppression reduces downtime in limestone ... - Quarry

The unit was situated to cover the immediate area around the primary impact crusher, a Universal 4650 that reduces the freshly-mined stone to 5 minus. What had been a primary source of airborne dust quickly cleared up, eliminating the periodic work stoppages on all but the windiest days, and Linwood officials stone production levels rise.

Dust emission from crushing of hard rock aggregates ...

In Quarry 2, drilling and hydraulic impact hammering, which located DW with respect to the dust measurements, lacked any notable effect on concentration results, since both operated only short time periods and drilling is generally shown to have significantly lower dust emissions compared to crushing.