Secondary Crushing Equipment

The simplest form of secondary crushing stage involves a single crusher, taking its feed by gravity flow direct from the primary with no interposed scalping separation. This is tantamount to making the over-all reduction in one machine, except of course that there will always be a certain amount of surge capacity between the two crushers.

Choosing the right primary crusher for your aggregate ...

Sep 27, 2019 · Primary crusher is the workhorse that takes blast feed sizes and turns them into smaller sizes that are manageable for other site components—the belts, the screens, and eventually any secondary crushers—on the road to a finished product.

Crushers - All crusher types for your reduction needs - liming

Cone crushers . Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages. Sometimes, however, the stone size of the processed material is small enough by nature and the traditional primary crushing stage is not needed.

Crushing 101 » Masaba Manufacturing

Oct 04, 2019 · Many producers refer to jaws as “breakers” meaning that they break the rock down to a size manageable for the secondary crushers. The numbers used in referring to jaw crushers, such as 3042, refer to the opening size at the top of the jaw. The 30 …

components of a secondary crusher - Ketel Service Nederland

They’re used to break those large pieces into something more manageable for the smaller crushers. If a jaw crusher is necessary, the reduced material is then fed into a finer crusher by a conveyor belt. After the secondary crusher reduces the material even more, it’s moved to …

Secondary crusher, Secondary crushing plant - All ...

liming QS331 is a compact, high quality, secondary cone crusher. Fitted with liming CS430 "S" type gyratory cone crusher, it is capable of accepting large feed sizes whilst achieving... impact crusher / mobile / compact / primary QI341... mobile impact crusher is the most versatile and cost effective mid-sized unit on the market.

Chapter 6 Crusher Supervisor and Operations

The secondary unit is basically the same as the primary crusher except it reduces the stone to an even smaller size. It consists of a reciprocating feed hopper, an overcrusher conveyor, a two-deck vibrating screen, a compression crusher, an undercrusher return conveyor, a revolving elevator wheel, a diesel power unit, and conveyors (Figure 6-4).

Secondary & Tertiary Crushing Circuits

The coarse material will be crushed by the secondary crusher. The fines will be taken out of the circuit. Once the secondary has finished with the ore it will be reclassified by a second set of screens with the oversize going to the tertiary crusher. The discharge of the tertiary is reintroduced to the screen deck to ensure that the ore size is ...

Everything You Need to Know About Rock Crushers | Kemper ...

Cone crushers are often placed within the secondary crushing station because they are versatile in terms of feed, closed side setting, speed, and throw. With cone crushers, though, it is essential to operate them at consistent choked settings to keep productivity up. 3. Tertiary/Quaternary/Final Reduction Crushing.

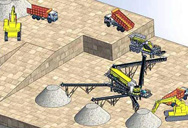

SAND, GRAVEL, AND CRUSHED STONE ON-THE-JOB …

by a secondary crusher, and sometimes a tertiary crusher. Raw material, of various sizes, is brought to the primary crusher by rear-dump haul units, or carried by a w heel front- end l oader . Pr imar y cr ushi ng reduces thi s run- of -mine r ock to a more manageable size. The different types of primary crushers are: jaw crushers, gyratory

Crushing Equipment 101 | Kemper Equipment

They’re used to break those large pieces into something more manageable for the smaller crushers. If a jaw crusher is necessary, the reduced material is then fed into a finer crusher by a conveyor belt. After the secondary crusher reduces the material even more, it’s moved to …

Clearing Blocked Crushers - Health and Safety Authority

Primary crushing reduces excavated rock to a more manageable size. There are different types of primary secondary and tertiary crushers including jaw crushers, gyratory crushers, impact crushers, and autogenous crushers.

list of secondary crusher - apemonaco.org

China High Quality Cone Crusher Price List, Find details about China Cone Crusher Price List, Cone Crusher Cone crusher Appliions: Secondary crusher. Types of Crushers 911 Metallurgist. Aug 31, 2017 Pressure Crushers: This egory embraces the several types of gyratory to develop special crushers for secondary and fine-reduction work,

different types of primary crushers

Sep 09 2019 · There are so many similarities in the stone they do All these primary crushers reduce rocks to more manageable sizes The following are the different types of primary crushers and their uses Jaw Crusher 1 Jaw Crusher A jaw crusher has two metal surfaces This crusher uses these surfaces to squeeze rock between One surface opens and closes like a jaw

Crushers | Risk Management | SGS

Risk Management Crushers SGS toothed roll crushers and screw feed hammer mill crushers are designed and manufactured with the precision engineering and reliability that has made SGS a world leader in mechanical sampling systems for over 35 years.

How to Select the Right Primary Crusher

Apr 25, 2019 · The primary crusher is the engine that drives the rest of the plant; it’s the workhorse that takes blast feed sizes and reduces them to sizes that are manageable for other site components – the belts, the screens, and eventually any secondary crushers – on the road to a finished product.