Cement Cooling System - Efficient, Industrial Cement ...

The cooling of cement is an important step prior to storage in mitigating gypsum dehydration and subsequent moisture liberation which can lead to lump formation. Recommendations vary but it is generally accepted that with mill outlet temperatures of around 110ºC – 120ºC, cooling to below 80ºC …

Clinker Cooler - Cement Cooler | AGICO Cooler In Cement Plant

As the supporting equipment of cement rotary kiln, clinker cooler (also called cement cooler) is a kind of heat exchange device that transfers heat from high-temperature clinker to low-temperature gas. It plays an important role in the cement clinker production process and directly affects the cement …

Reliable high-performance clinker cooling | FLSmidth

The cooler inlet can be a source of downtime for many cement plants. That’s why we designed the patented ABCTM Cooler Inlet, an advanced inlet system built specifically to eliminate the downtime associated with snowmen and dead-zones. The result is higher uptime for your plant …

Clinker Grate Cooler for Cement Plant

Clinker Grate Cooler Processing capacity: 800-4000t/d Applications: Cement, silicate products, new building materials, refractory materials, glass ceramics and other... Applicable materials: limestone, cement clinker…

Grate Cooler – Clinker Cooler | AGICO Grate Cooler In ...

The clinker can be quenched from 1300-1400℃ to below 100℃ in a few minutes. HCFC reciprocating grate cooler is one of the hot-sale grate coolers produced byAGICO. It is a kind of large hydraulic controlled grate cooler …

Grate Cooler|Rotary Cooler for Clinker Cooling

n a cement plant, grate cooler is a basic machine in the calcining cement system, its main function is to make the ripe cement material to next system. At the same time, the grate cooler could offer …

Claudius Peters - ETA Cooler Holcim Untervaz - ENG - YouTube

Dec 02, 2015 · Claudius Peters has identified that the Clinker Cooler is one of the most maintenance and process sensitive areas in the operation of a cement plant …

KHD PFC2 Cooler - YouTube

Jun 09, 2016 · The next evolution in KHD cooler technology. WORLDS BEST TREE FELLING TUTORIAL! Way more information than you ever wanted on …

Premium solutions for the cement industry

A plant or a piece test. Whether you are looking for an entire cement plant or a single piece of equipment, we are the premium supplier. For new plants, we cover everything from evaluating initial …

Problem with cooling fan of IKN grate cooler - Page 1 of 2

Dec 01, 2011 · Re: Problem with cooling fan of IKN grate cooler. Dear, Please send the Kiln and cooler operation data along with Kiln feed chemistry as well as clinker then it will be easy to answer your …

Thermal Imaging for the Cement Industry

Thermoteknix Systems designs and builds cutting edge thermal imaging technology for use in today’s modern high production cement plants throughout the world. The modern cement plant represents a …

Cement kiln - Wikipedia

Portland cement clinker was first made (in 1825) in a modified form of the traditional static lime kiln. The basic, egg-cup shaped lime kiln was provided with a conical or beehive shaped extension to increase draught and thus obtain the higher temperature needed to make cement clinker.

Process Fans Used in Cement Industry - Reitz India

Cement industry uses large number of cooling fans usually between 5 to 15 in one clinker line based on the kiln capacity. Cooling fans are used to blow cold air to the cooler and to cool the clinker from …

Home - IKN - IKN GmbH

IKN - Heat Up ... Cool Down. Innovative solutions for the cement industry made in Germany. From clinker cooler retrofits to kiln upgrades and complete greenfield pyro systems, we offer what it takes to build and operate profitable cement plants.

Clinker Cooler - Mineral Processing & Metallurgy

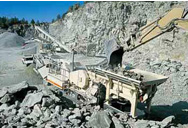

A modern 4½ x 70-ft Air-Quenching grate cooler in a US cement plant. A cooler this size will cool clinker at a rate of 100 barrels per hour.

The cement kiln - Understanding Cement

From an environmental and a cost viewpoint, the cooler reduces energy consumption by extracting heat from the clinker, enabling it to be used to heat the raw materials. From a cement performance …