PPT – CEMENT INDUSTRY PowerPoint …

2016 stone Cement Industry Report - Global and Chinese Market Scenario - The Global and Chinese stone Cement Industry, 2011-2021 Market Research Report is a professional and in-depth study on the current state of the global stone Cement industry with a focus on the Chinese market. | PowerPoint PPT presentation | free to view

Cement manufacturing process - LinkedIn …

Cement manufacturing process 1. Universityof Sulaimani College of Science chemistry dept. Cement manufacturing process prepared by: 1-Haval Arf 2-Rawand Wahid 2. Cement and history Cement is a common construction material, that hardens in the presence of water. Cement is used as a binding material in mortar, concrete, etc. Cement has been made since Roman times, but over time the …

Cement - LinkedIn SlideShare

CEMENT INDUSTRY PROFILE Prerna Mehrotra MBA Sem 3 ... semi-dry process technology. •The cost of Cement is 29% energy; 27% raw materials; 32% labour and 12% depreciation CEMENT MANUFACTURING PROCESS 8. Growth Rate Investments Exports FDI and GDP ECONOMIC STATUS OF THE CEMENT INDUSTRY 9. •India is the world’s second largest producer of cement with total …

types of cement manufacturing process ppt

cement training course in powerpoint . Cement Manufacturing Cement Manufacturing Process Hydration of Cement Hydration of cement compounds Setting of cement Cement Types Cement Properties Download cement training course in powerpoint web share 2016-07-24T09 17 00-07 00 5 0 stars based on 35 reviews cement course online with theses elements Historical Development Manufacture of Cement …

Cement Manufacturing Process In Ppt - …

PPT – CEMENT INDUSTRY PowerPoint presentation | free to . Cement Market Industry Trends - Bharat Book Bureau provides the report, on "Cement Market - Industry Trends, Manufacturing Process, Plant Setup, Machinery, Get Price. powerpoint presentation on cement manufacturing process india. ppt cement manufacturing process - … Machinery (cement manufacturing process ppt india) in …

Wet process for cement production ppt

Wet process for cement production ppt. The cement manufacturing is done by majorly by two methods known as wet process and dry process depending on their mixing is done with water or without water The wet process of cement manufacturing too popular for several decades because of the possibility of more accurate control while raw material mixing . Get a Quote. Related Products. PDF Analysis Of ...

cement industry ppt slides on marketing and …

05.03.2013 · » business process diagram of cement industry in ppt … See next slide Detailed … The choice of process may depend on the firm’s marketing plans and … »More detailed. cement sector ppt slide; slide designs for thermal power marketing powerpoint free download; powerpoint presentation on ready mixed concrete; power point presentation of regional sales manager of cement industry; ppt ...

Power Point Cement Industry |authorSTREAM

20.09.2010 · SEMINOR PRESENTATION CEMENT INDUSTRY IN INDIA Presented by A.Meenaiah M.A, M.phil, (PhD) Lecturer in Economics N.G College Nalgonda (A.P) Cell No. 9490138118 . Introduction : Introduction The “Cement Industry” occupies an important place in both building industrial base of a country and for providing an infrastructure for the development of the national economy. …

Cement Manufacturing Process | Phases | Flow …

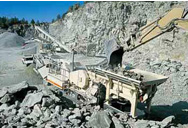

Cement Manufacturing Process Phase II: Proportioning, Blending & Grinding. The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding. Generally, limestone is 80% and remaining 20% is the clay. Proportioning of raw material at cement plant laboratory. Now cement ...

The Cement Manufacturing Process - Thermo …

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kiln. In this process, the stone bonds of the raw materials are broken down and then they are recombined into new compounds. The result is called ...

Supply Chain Management in Cement Industry

• Can SCM generate value in the cement industry? Methodology Industry Analysis: 1. Competitive Strategy (Porter, 1980) Supply Chain : Strategy: 2. The essence of excellence (Lapide, 2006) Supply Chain : Operating Model: Processes. Analysis. Product. Analysis. 3. SCOR Model: 4. Four Types of SC Design (Reeve et al. 2005) 5. Push - Pull Boundaries (Simchi-Levi et al., 2008) 6. Demand ...

Cement Industry Overview

The cement industry has boosted efficiency by concentrating new capital investment in plants that use the dry process of cement manufacture, and by phasing out operations that rely on the more energy-intensive wet process. Since 1974, the number of wet process kilns has dropped from 234 to 25 -- a decline of 89 percent -- while the number of dry process kilns has only been reduced from 198 to ...

CHAPTER 3.0 CEMENT MANUFACTURING PROCESS

Chapter-3 Cement Manufacturing Process 38 This area of the Kiln is called the Burning zone where the temperature is about 1400-1500 oC. The hot gas generated in the burning zone of Kiln is sucked through a preheater cyclone by a fan called Preheater Fan which also creates a cyclonic effect on the preheater cyclones. Due to cyclonic effect and gravitational force, the material is gradually ...

Cement and its effect to the environment: A case study in ...

The cement industry recognizes its responsibility to manage the environmental impact, associated with the manufacturing of its product. Mainly, there are two types of cement production process; such as wet process and dry process. The preparation of cement includes mining, crushing, and grinding of raw materials, calcining the materials in 1408. rotary kiln, cooling, resultant clinker, mixing ...

SPL UTILIZATION IN CEMENT & STEEL INDUSTRY Technical Report

SPL UTILIZATION IN CEMENT & STEEL INDUSTRY Technical Report 2 Prepared By: Nitin Tiwari 1. Introduction This technical report is created to provide general information on processing of SPL. There are a number of ways including direct charging in cement kilns as fuel substitute or feed mix received after detoxification process can be used in various Steel & clay bricks manufacturing. This ...

Spent Pot Liner Utilization in Cement Industry Steel Industry

• Recycling is an attractive and proven option; Best may be for Cement & Steel Industry • Co-processing in cement has already been established as the proven and most reliable option for disposal of SPL, Cement plant in Europe, Australia , Latin America are regularly using SPL as part of their Alternative fuel usage strategy. SPL – An Alternate Fuel/Raw mix additive 18 No. of Large Cement ...

Supply Chain Management in the Cement Industry

the cement industry planning process is centralized and optimization oriented. There is no constraint in the availability of cement main raw materials with the exception of some countries where subsoil ownership regulations applied. Cement manufacturing is capital and energy intensive where cement truck delivery is restricted due to its low value-to-weight ratio. quarries: HIGH • Oligopoly ...

Cement manufacturing dry process. - YouTube

30.12.2017 · #cement-manufacturing-process #cement-manufacturing-dry-process #cement-tech-with-nic #cementplant #cement #cement-tech जानिए सीमेंट उत्पादन की विधि ...

Combustion and emissions analysis of Spent Pot …

SPL materials can be co-processed successfully in cement industries as alternative raw materials for cement production. SPL is believed to contribute in reducing NOx emissions from cement production mainly through two ways; 1) The SPL materials help reduce the kiln temperature, or melting point of cement raw mix thus reducing the NOx emissions which are temperature dependent, and 2) cyanide ...